Production policies

Integrated management of product manufacture and quality

The assurance of safety and quality of the product offered to our clients is one of our top-priority corporate activities.

At Kyoritsu Chemical & Co., Ltd., we take appropriate measures to cope with a variety of risks by constructing a stable supply system upgraded based on the internal response process in an effort to improve client satisfaction.

Product supply (manufacturing) – Integrated management system

Our integrated management system enables us to improve the quality of the products supplied based on a system which manages a variety of items relating to supply in an integrated manner.

Quality improvement

Acceptance inspection of raw materials (entry management)

To maintain a certain level of quality of products, we set a unique standard and items for raw material acceptance tests.

Analysis and product inspection (exit management)

Ensure reliable output management through quality inspection of all products: Introduced inspection and analysis equipment which provides quick analysis of quality abnormalities and proposes a new material analysis method.

Production management

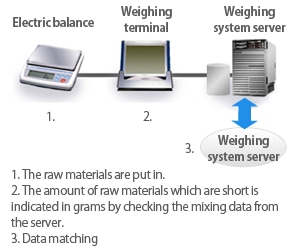

Weighing system

Raw materials are prevented from being erroneously compounded by combining an electric balance and server, and simultaneously performing barcode management. Also, it is feasible to perform tracking at the level of the raw materials to be used.

Production process

Introduced manufacturing process management based on a weighing system and work environment management, including layout of a clean room and temperature/humidity management, for the manufacturing of high-purity products.

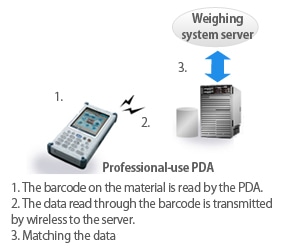

Material management

Materials are managed on a real-time basis through the use of the professional-use PDA, which is connected with the barcode system.

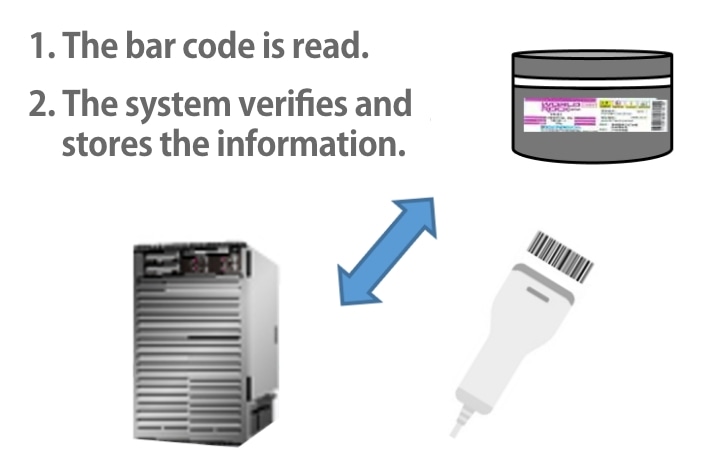

Shipment management

Individual identification codes are assigned to all products stored in a temperature-controlled warehouse.

Reliable shipment management is realized by reading these codes upon shipment.

Stable supply

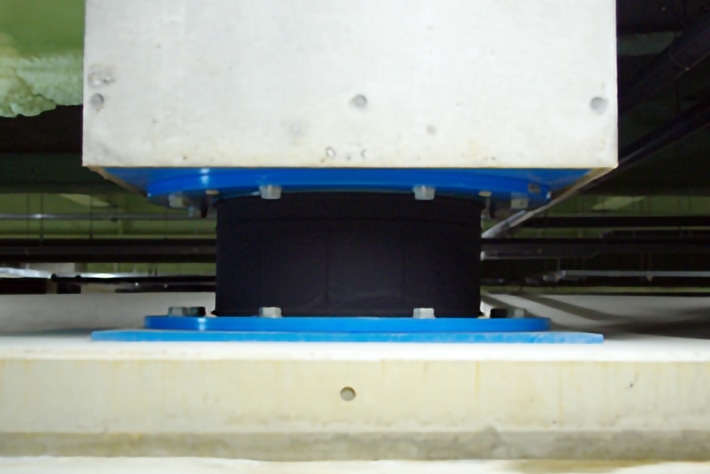

Earthquake-proof structure

If plants suffer large-scale earthquakes, which have been increasingly frequent recently, not only the local facilities but also plants in other areas would be obliged to stop their manufacturing activities.

By adopting earthquake-proof structures for our research and manufacturing facilities, we have built up a system which ensures that our employees and facilities are protected from a large earthquake, and our products are always supplied in a stable manner.

In-house power generation

Stable power supply is indispensable for business operations and stable production of products. On the other hand, nowadays, there is a concern about the stable supply of power, which is a risk factor for stable continuity of business.

We are equipped with an in-house power generator to enable normal operation of our entire business operations for research and manufacturing even in case of a power failure, and are able to maintain stable production.