Three Strengths

Three Strengths of Kyoritsu Chemical & Co.

Based on the motto “Designing adhesion technologies”, we offer proposals

that leverage the expertise we have accrued since our founding as a trading company specializing in adhesive products.

Here, we introduce our three strengths that enable us to provide you with value.

-

01

Adhesion Technologies

-

02

Challenging Possibilities-Advanced Evaluation Technologies

-

03

Solutions for Your Needs

01 Adhesion Technologies

UV curing adhesives we have developed through our own research offer excellent properties such as high-precision fixing, instant curing, and high airtightness, and are widely adopted in the field of electronics.

We aim to create next-generation technologies not only by improving the high functionality of materials,

but also by combining multiple core elemental technologies.

We continue to innovate by promoting the higher functionality and evolution of each elemental technology

as well as by fusing various core and new technologies to accelerate the development of new products and new materials.

02 Challenging Possibilities-Advanced Evaluation Technologies

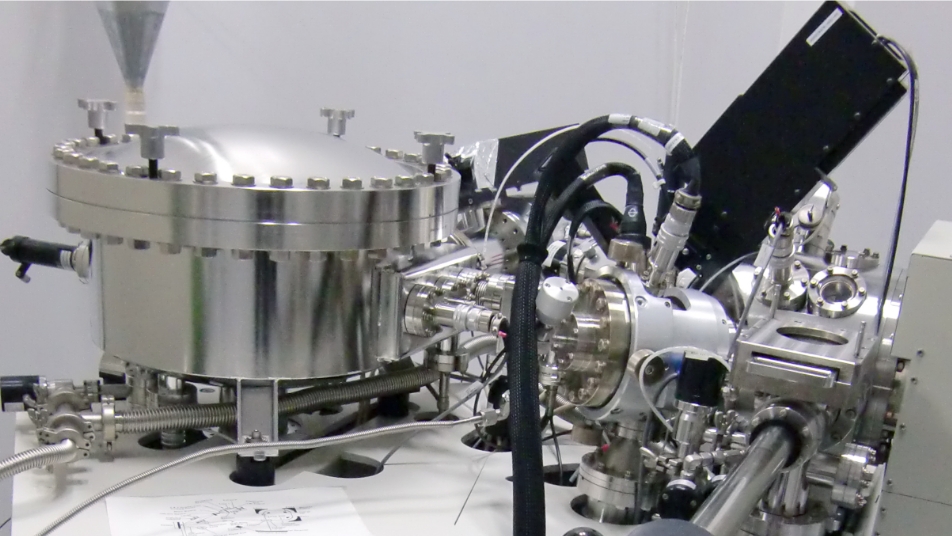

Evaluation technologies play an important role in the development of new chemical technologies and products. We have introduced some of the world’s most advanced analytical systems and are equipped with the highest level of evaluation technologies.

-

Various evaluation facilities

We have introduced a manufacturing system that enables us to actually assemble liquid crystal displays, including a “micro contact angle analyzer” that can confirm and analyze wettability of the surface of a single hair through images, the “FE Type EPMA”, the first of its kind introduced by a private sector company, that allows for easily analyzing components in submicron microscopic areas by color mapping, and so on.

-

High analytical capabilities

We are equipped with ultra-advanced equipment and capabilities that enable accurate visual observation and analysis of chemical reactions even under cutting-edge situations where nano-level science has become necessary.

03 Solutions for Your Needs

We operate with the mission of “Designing adhesion technologies for your needs”. We create optimal adhesive solutions just for you by sharing in your challenges and dreams by being creative with ideas geared toward your business.

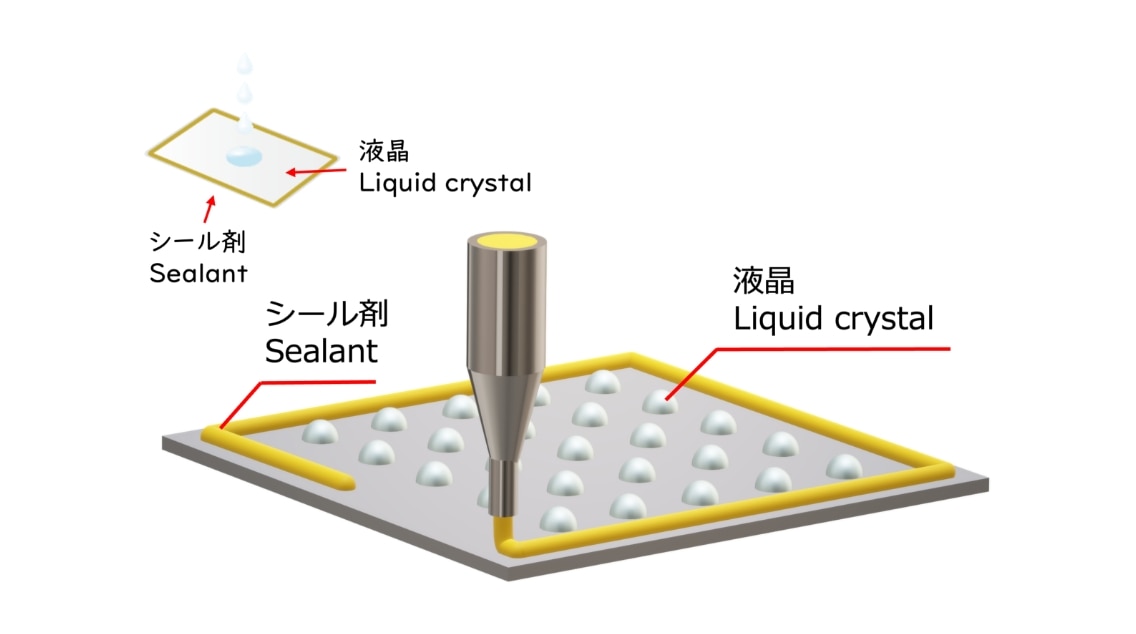

Solution examples 01 LC dropping method for displays.

ProblemThe manufacturing process takes too much time with the injection method.

Solution technologyDeveloped “UV-curing sealing agent” for the dropping method.

The “dropping method” has now become the standard for LC display adhesion. But at the time of its development, it was impossible for two liquids not to react chemically with each other. Working together with our customers who trusted our capabilities, we developed a UV-curing sealing agent that would prevent chemical reactions between the liquid crystal and adhesive, realizing an ideal method.

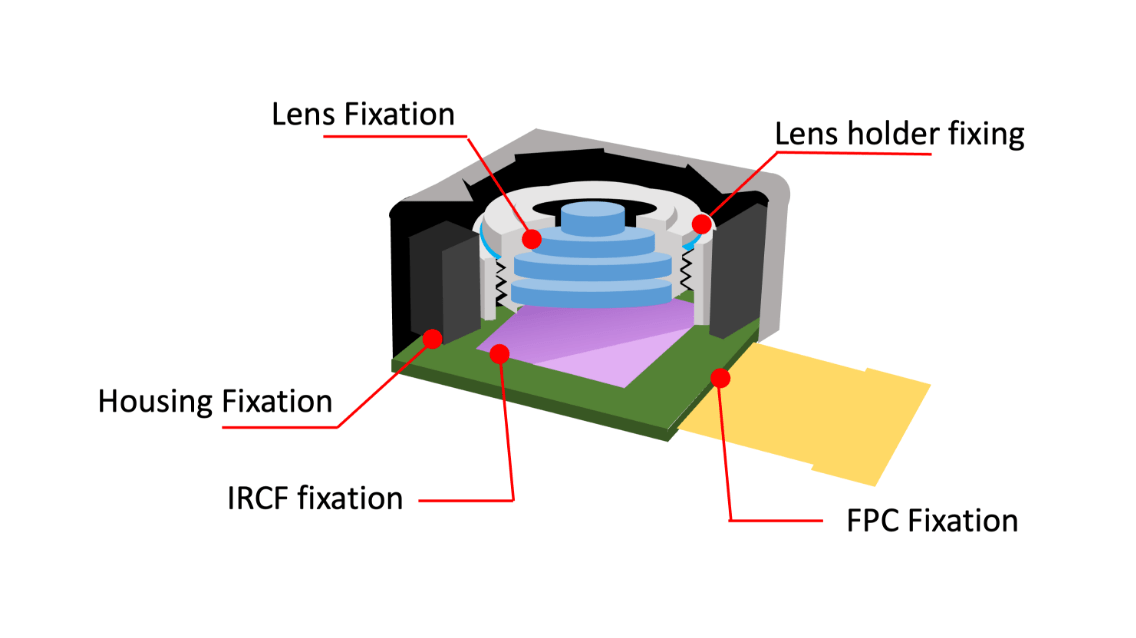

Solution examples 02 Mounting cameras on mobile phones.

ProblemFurther higher functionality of adhesion technologies for adapting to miniaturization.

Solution technologyDeveloped a variety of adhesive products for each part.

We replaced all screw fastenings and metal part fittings in digital cameras with adhesives Utilizing this experience, we have developed a variety of adhesive products optimal for different parts of mobile phone camera modules.

Even today, we continue to meet the ever-changing demands for higher functionality and precision.

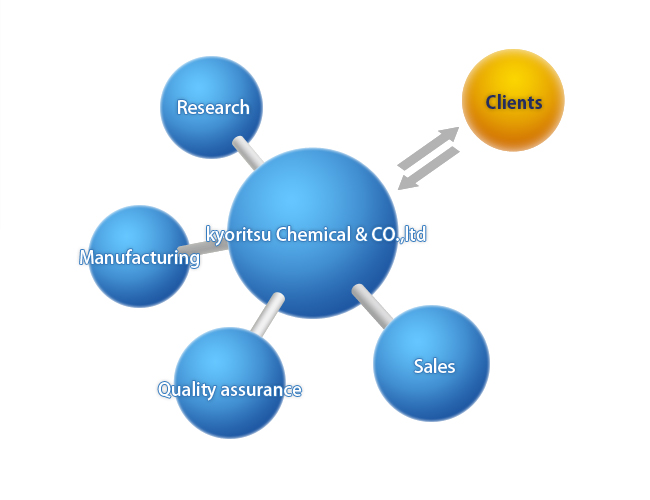

Speedy product development system that supports solutions

Under the “Pair-System”, our sales, development, quality and manufacturing departments operate in a coordinated manner. By sharing all information received from our customers as well as all information from the engineering side, we speedily develop products by accurately understanding the needs of our customers.

Product Development Flow

-

Preliminary discussion

Explain your challenges, problems or needs.

-

Product planning

We propose solutions for your needs.

-

Research & development

We customize or develop a product based on specific requirements.

-

Prototyping and evaluation

Mutual evaluation based on prototypes to determine specifications.

-

Manufacturing and inspection

We flexibly accommodate your desired delivery date and quantity, and manufacture under strict quality controls.

Responsible management and execution even after technological development

After the development of an adhesive product and technology that is satisfactory to you, we manage and execute manufacturing, storage and logistics in a responsible manner.

-

Shipment

We deliver your products using a transportation means suited to the product’s characteristics to your designated location.

Safe and secure delivery

By setting the manufacturing, storage and shipment schedule according to your product production plan and usage amount, we deliver the adhesive products safely and securely to the plant where they are needed.

Our proven technologies continue to expand globally.

Our products are used in various electronics products, such as for the fixation of digital camera lenses,

fixation of light emitting/receiving elements on optical pickup devices, bonding of displays and lenses,

liquid crystal sealing agents, and more.

Our business is not limited to Japan.

We have established overseas affiliates in Shanghai, Taipei and Seoul

as regional bases around Asia where the electronics industry is developing rapidly,

and we are further expanding globally to the United States and Europe.

Please feel free to consult with us for solutions to your needs.

We will offer a proposal from planning to the realization of a product that will solve your needs.

We welcome consultation on any matter. Please feel free to contact us.